Maybe it’s because we’ve all come to appreciate the little things in life a bit more, but it was a very happy day here at Industrial Packaging last week, when we took delivery of a fantastic, hi-tech new machine for our core and tube production facility!

Core winders play a key role in allowing us to supply high-strength industrial cores to industries manufacturing products such as flexible film, silage wrap, labels, tape and textiles. Wrapping these types of products around cores is a very cost-efficient way to store and transport them, and maintain them in top condition.

The core winders work in conjunction with our core dryer, another custom engineered machine, which ensures high radial crush strength in the newly produced cores.

The core winders work in conjunction with our core dryer, another custom engineered machine, which ensures high radial crush strength in the newly produced cores.

We currently have two other winders – the new one makes three – so this investment effectively increases our production capacity for these products by 33%, as well as reducing lead times for our customers.

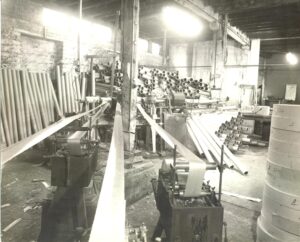

Check out the old photo of one of Industrial Packaging’s first core winders, at our original factory in Dublin’s city centre. It’s so interesting to compare the old and the new machines – it really brings home how constantly investing in improvements in technology benefits the manufacturing process and, ultimately, product quality.

Furthermore, a key element of our corporare sustainability goals is to manufacture our products as efficiently as possible. Investing in our infrastructure like this contributes to hitting our annual energy efficiency targets in the area of production.